Aramco Standard Duct Bank, Conduit Installation, Underground Cable System, Bends Standard

This article is about Aramco Standard Duct Bank, Conduit Installation, Tips for Conduit Installation, Underground Cable System, Bends Standard and focusing to the engineers, technicians and supervisors. You will find lot of documents related to this article. Just navigate our website www.QCSKILLS.com and find more articles.

Duct Banks:

- Consist of either hot dip galvanized rigid steel or PVCconduit, in case in concrete.

- 75 mm of concrete from the outside surface of the duct bank to any conduit or reinforcing steel.

- Fabricated spacers shall be used at intervals not exceeding 2.4 Meter.

- The spacers shall provide a minimum conduit separation of 50 mm for 2 inch conduit.

- For equipment, devices, or appropriates certified as intrinsically safe, only those that are certified are category EEx or AEx “ia” shall be used.

- All metal cable trays, enclosures used for intrinsically safe wiring shall be grounded to the plant grounding system with a min of # 4AWG copper wire with green insulation.

- Cable Tray material shall be galvanized, carbon steel in indoor air condition area.

- Bare copper cable does not used in or on aluminum cable tray.

Conduit Installation:

Conduit fittings and

accessories include conduits and pull boxes:

- Conduit over and gaskets

- Conduit Seal

- Conduit Unions and Couplings

- Drain

- Breathers

- Plugs

- Conduit Connectors reducers

- Expansion fittings

- Straps and Clamps

- Bushing

- Cable and duct seal, etc.

Tips for Conduit

Installation:

- Conduit Expansion fitting shall be provided in indoor 30 Meter.

- Conduit Puller J/B shall be provided every 25 Meter.

- Pull Box to Pull Box maximum bends acceptable in 360 degree without 90 degree bend.

- Support (Bending) does not occur NEC-344

- Pull & JB are Installed & Securely fixed as per NEC-314.28

- All connection of conduit shall be made by the pipe thread with engagement of at least 5 threads in the effective threaded portion.

- The connection part shall be painted by the zinc primer.

- When EYS and EZS Series (Explosion proof Conduit Sealing Fittings only).

Tips: 1- Sealing fittings are used to seal cables in conduit entering enclosures; a conduit union shall be installed between the sealing fittings and the enclosure.

2- Restrict the passage of gases, vapors or flames from one portion of the electrical installation to another at atmospheric pressure and normal ambient temperatures.

3- Limit explosions to the sealed off enclosure.

4- Limit pre-compression or pressure “piling” in conduit systems

- When EYD and EZD Series (Explosion proof conduit sealing fittings with drain).

Tips: 1- Drain to provide continuous, automatic drainage of condensate.

2- Large openings with threaded closures to provide easy access to conduit hubs for making dams.

3- Integral bushings to protect conductor insulation from damage.

4- Taper tapped hubs to ensure ground continuity.

- NPT type accordance with UL34E 34997 or CSA (Canadian Standard) LR 9795.

- Seal fitting shall not be less than ⅝ inch.

- Sealing compound shall be 35 oC to 85 oF.

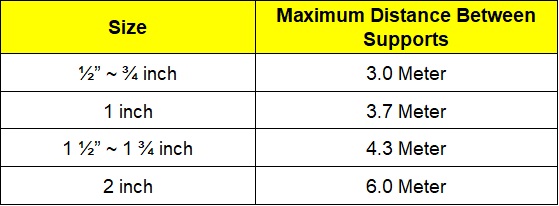

Support for Rigid Metal Conduits:

- Seals are provided in conduit & cable system to

minimize the passage of gases and vapors and prevent the passage of flame from

one portion the electrical installation the conduit.

- Bushings: Where

a conduit enters a box, fittings or other enclosure a bushing shall be provided

to protect the wire from abrasion.

Bends:

Number in one run:

There shall not be more than the equivalent of four quarter bends (360

degree total) between pull point to point.

Mandrel Testing:

Testing of underground duct bank and bend radius of conduit

is 90 degree. When union cannot be

avoided in underground conduit installation, unions shall be protected with

heat shrinkable sleeves.

Conduit and cable sealing shall be installed in accordance

with NEC-505.10. Conduit seals shall be installed within 450 mm (18 inches)

from the enclosure.

PB: Pull Box

RGS: Rigid Galvanized Steel.

Split Conduits:

Split conduit

Installation shall be used to repair existing conduits which contains existing

cable these conduits shall be installed in accordance with the manufacturer’s

recommendations or NEMA TCB2 User manual for the installation of order ground

plastic conduits.

- We can use maximum

bend in one conduit (Point to Point) 360 degree, but we have to avoid 90 degree

bend or sharp bends.

- If there is sharp

bend so we can perform Mineral Test.

- Direct buried

conduits (Underground) shall be threaded, rigid steel per accordance ANSI C80.1

and addition it shall be hot dip galvanized and PVC coated as per NEMA RN1

(minimum thickness of PVC 1 mm) or PVC conduit type DB-120 (Minimum elasticity

500-000 PSI) as per NEMA TC6 & TC8 type.

- Concrete incase

conduit shall be threaded, rigid steel as per ANSI C80.1 and in addition it

shall be hot dip galvanized.

- Conduit Installed

exposed (not embedded in walls) above grounding in outdoor industrial

facilities shall be threaded rigid steel per ANSI C80.1 and in addition it

shall be hot dip galvanized.

- Conduit above

ground in severe corrosive environments shall be as threaded, rigid steel as

per ANSI C80.1, in addition shall be

factory PVC Coated (minimum thickness of PVC 1 mm) as per NEMA RN-1.

- Electrical Metallic Tubing (EMT) is acceptable only in

non-hazardous indoor locations. EMT shall comply with the requirement of ANSI

C80.3

- Intermediate metal

conduit (IMC) is prohibited.

- The Minimum conduit

size shall be ¾ inch, except for instrumentation wiring inside building.

- Conduit and

threaded conduit fitting shall have tapered (NPT) threads in accordance with

ANSI / ASME B1.20.1

ANSI C80.1 Rigid Steel Conduit-Zinc Coated

ANSI C80.3 Electrical Metallic Tubing – Zinc Coated (for indoor only)

- Process Piping

shall be used to support conduits.

- Flexible conduit:

shall be used at instrument end of the conduit to provide isolation from

vibration against thermal expansion of the rigid conduit systems.

- Conduit sealing

shall only be poured at temp between 35 oF to 85 oF

- The sealing

compound shall provide a seal against passage of gas or vapors through the seal

fittings.

- The minimum

thickness of the sealing compound shall not be less than ⅝ Inch.

- Conduit seal

fitting plug is painted with red color and non poured seal fitting are painted

with green color.

- Gap selling of

expansion splice palate 25 mm (gap max)

- 50 oF or 10 oC gap is 9.5 mm (Standard)

Duct Bank Installation or

Underground cable system:

Conduit size shall be as per design of duct bank to be

installed with minimum gap from wall to wall shall be 75 mm. Support of Conduit

to be fixed every 2.4 Meter. Support shall be PVC material anchor type.

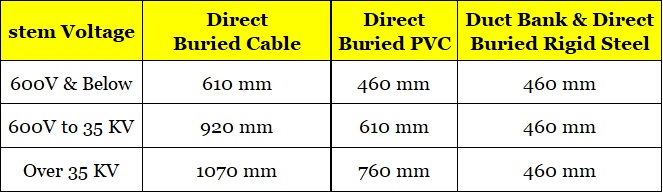

The minimum

depth of burial requirements for underground installations shall be as per: